Discover Our Process

The local Ministry of Environment conducts an examination of the designated area, and based on the outcomes, they may either grant or deny approval for tree harvesting.

Our founder, Bernardo Urbina, personally engages in the selection and approval process for Monkey pod and Parota logs, which he procures from local farmers situated in the rural regions of Costa Rica.

Then, with the completion of all the paperwork, the acquisition of a "yellow tag" permit is secured to facilitate the transportation of the logs to the mill.

Upon arrival at the Mill, we undertake the unloading of the logs, conduct a meticulous inventory check, and assign a distinct number to each Monkey pod and Parota log categorizing them based on their size and species.

Bernardo Urbina, along with his team, deliberates on the optimal approach for milling each log, ensuring the production of unique slabs.

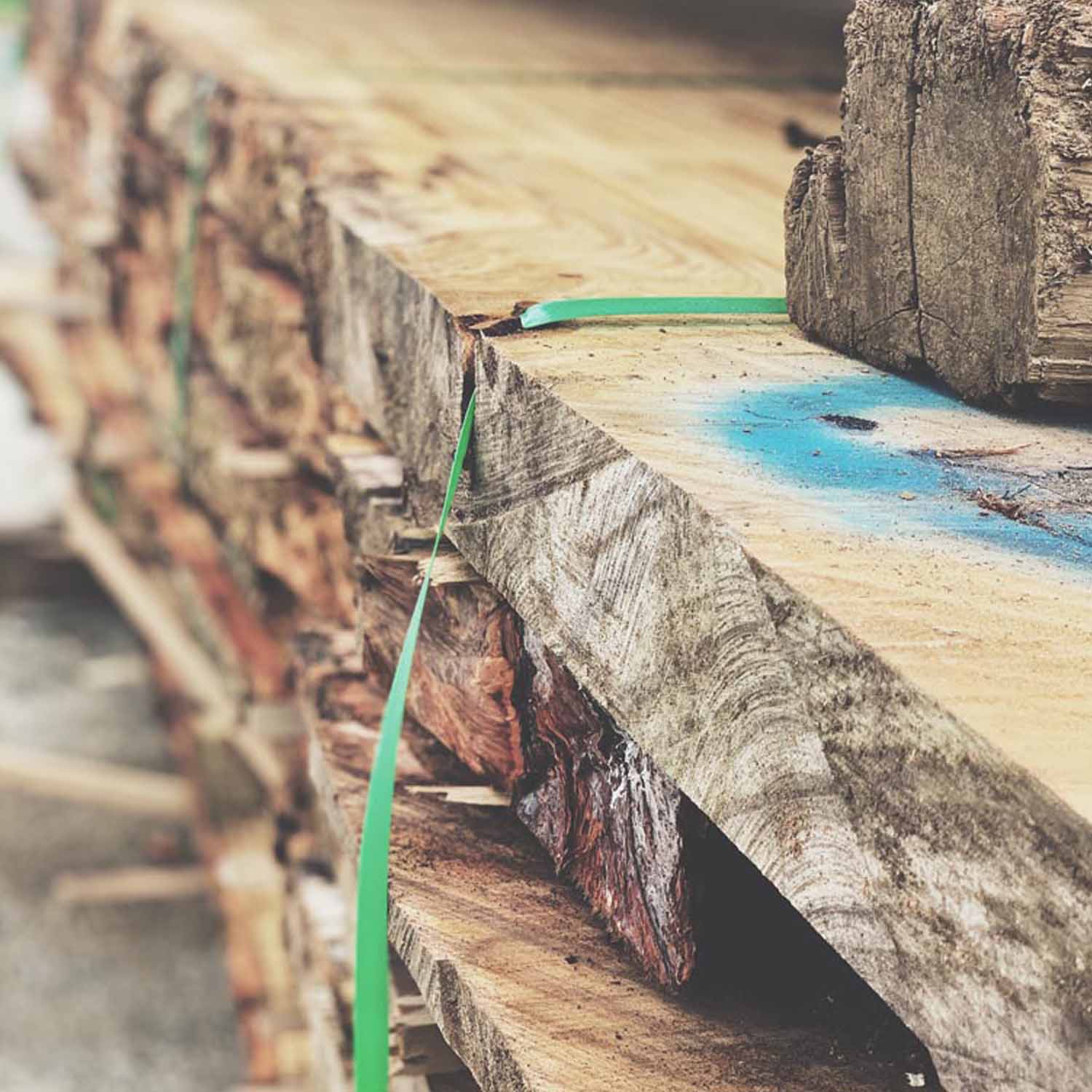

Subsequently, as the slabs are processed, they undergo stickering in preparation for their transfer to the warehouse, where the kiln is located.

Each slab is methodically stickered, maintaining a spacing of 12-16 inches, and undergoes a pre-drying phase lasting 1.5 months before progressing to the kiln.

Our kiln infrastructure comprises three carts, each with a capacity of 15 tons, facilitating the drying of 30 slabs per cart—amounting to a total of 90 slabs.

The kiln operates using sophisticated Italian software, integrating four strategically positioned sensors on the slabs to monitor their current moisture levels.

Additionally, the system incorporates relative humidity sensors within the kiln, four exhaust flaps, four bidirectional fans, and an extensive 12-meter-long stainless steel heating source. These components collaboratively function, both synergistically and wirelessly, adhering to a meticulously designed computer program.

This program ensures a gradual and efficient drying process, aligning with our predetermined moisture content specifications.

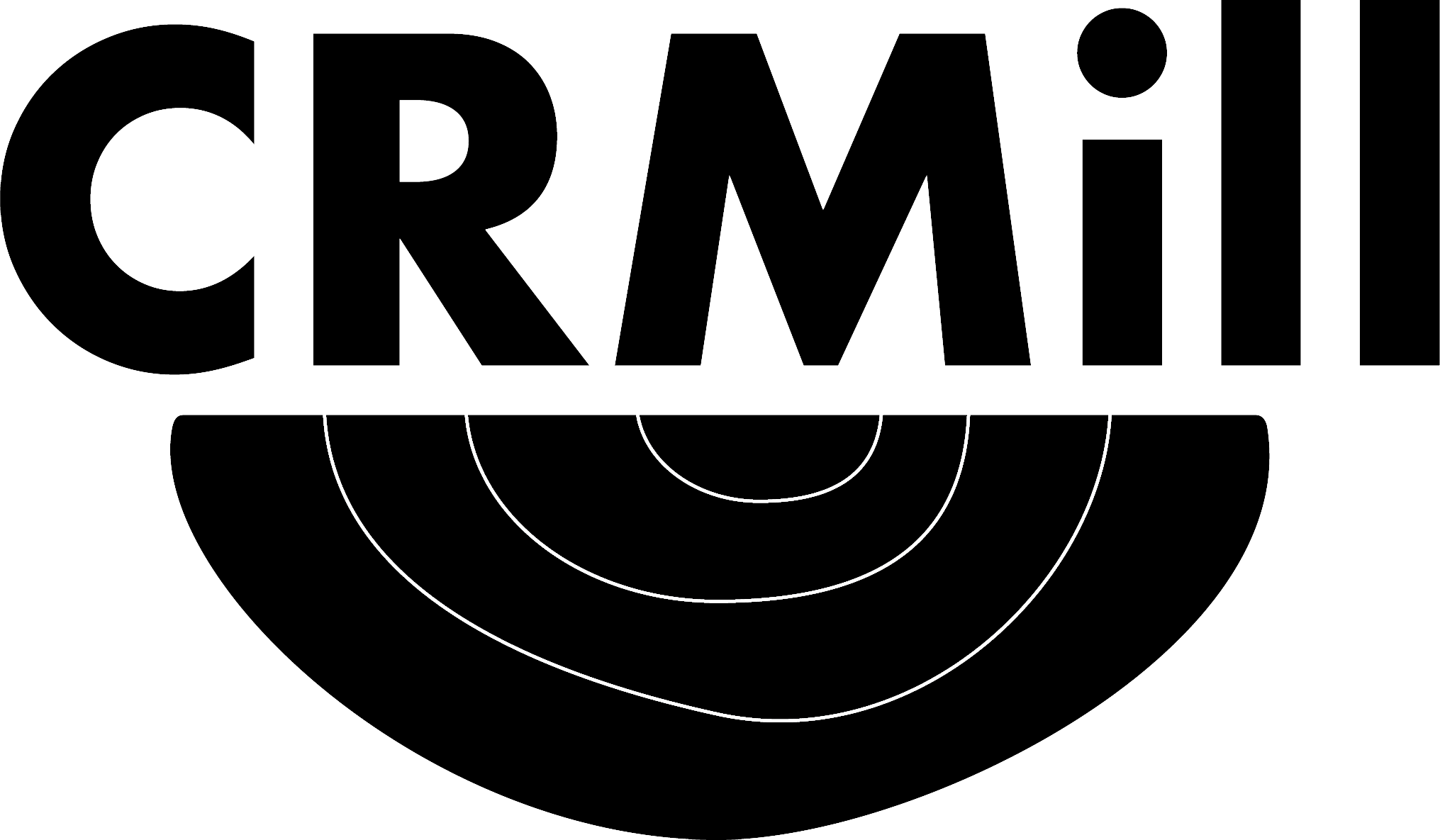

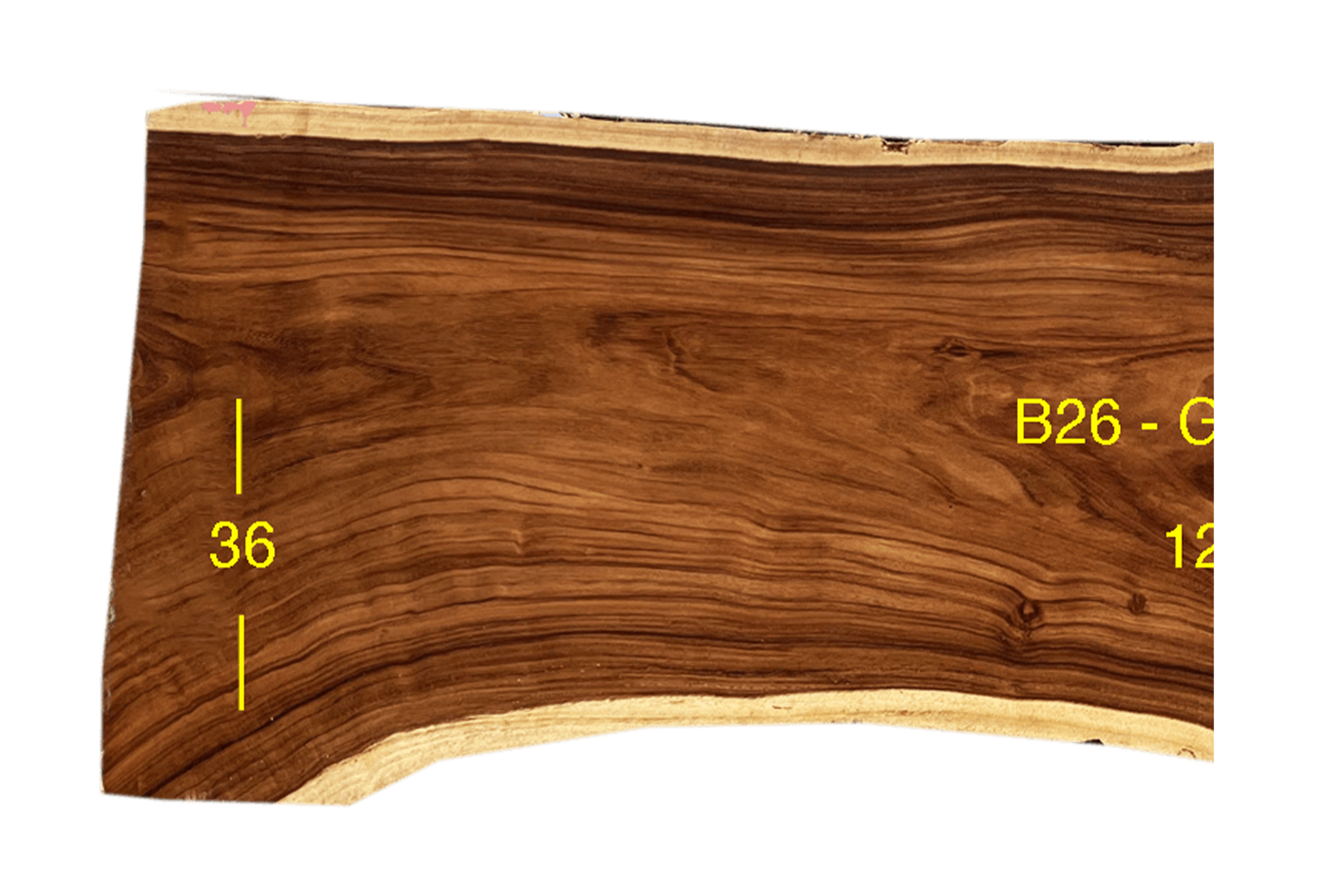

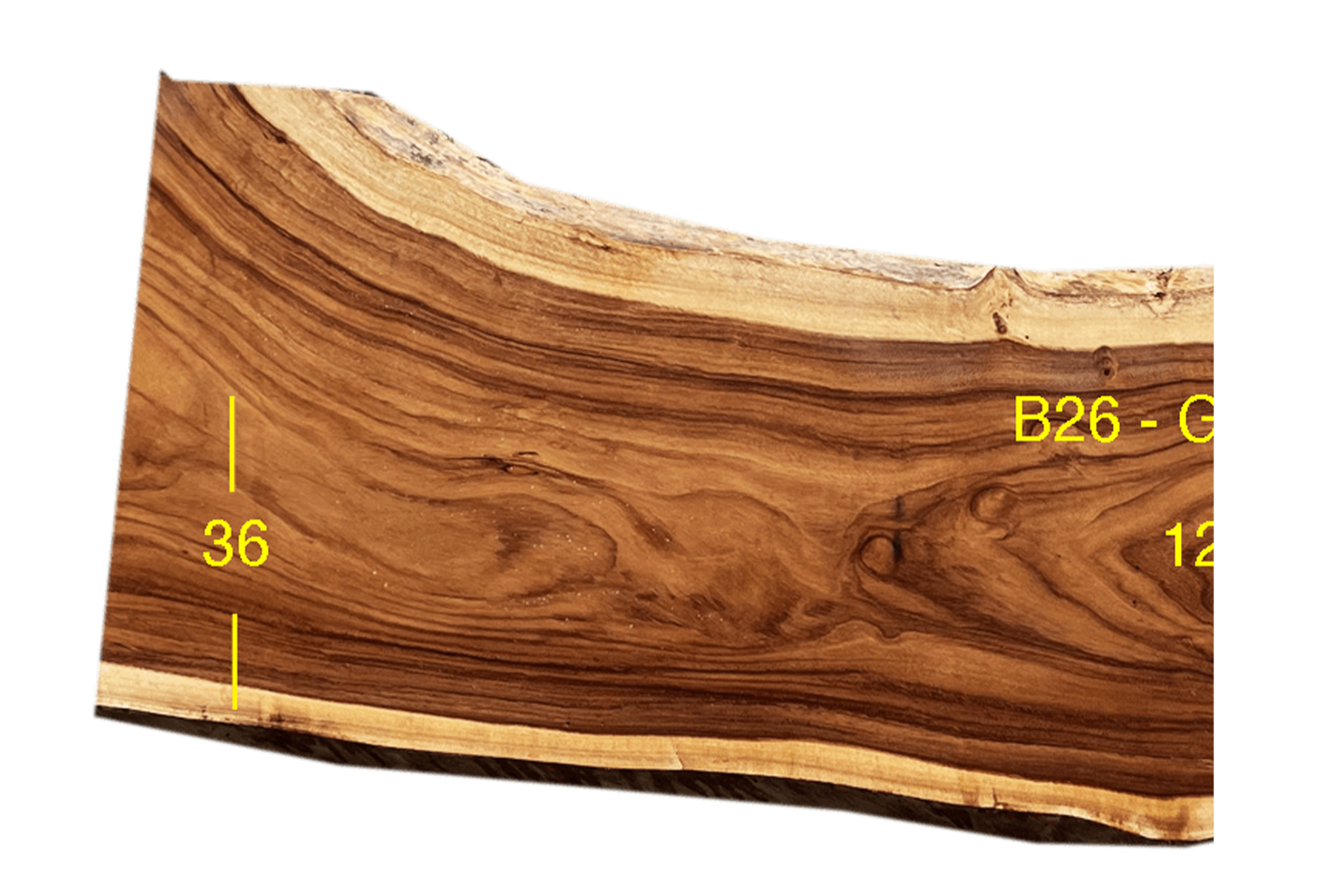

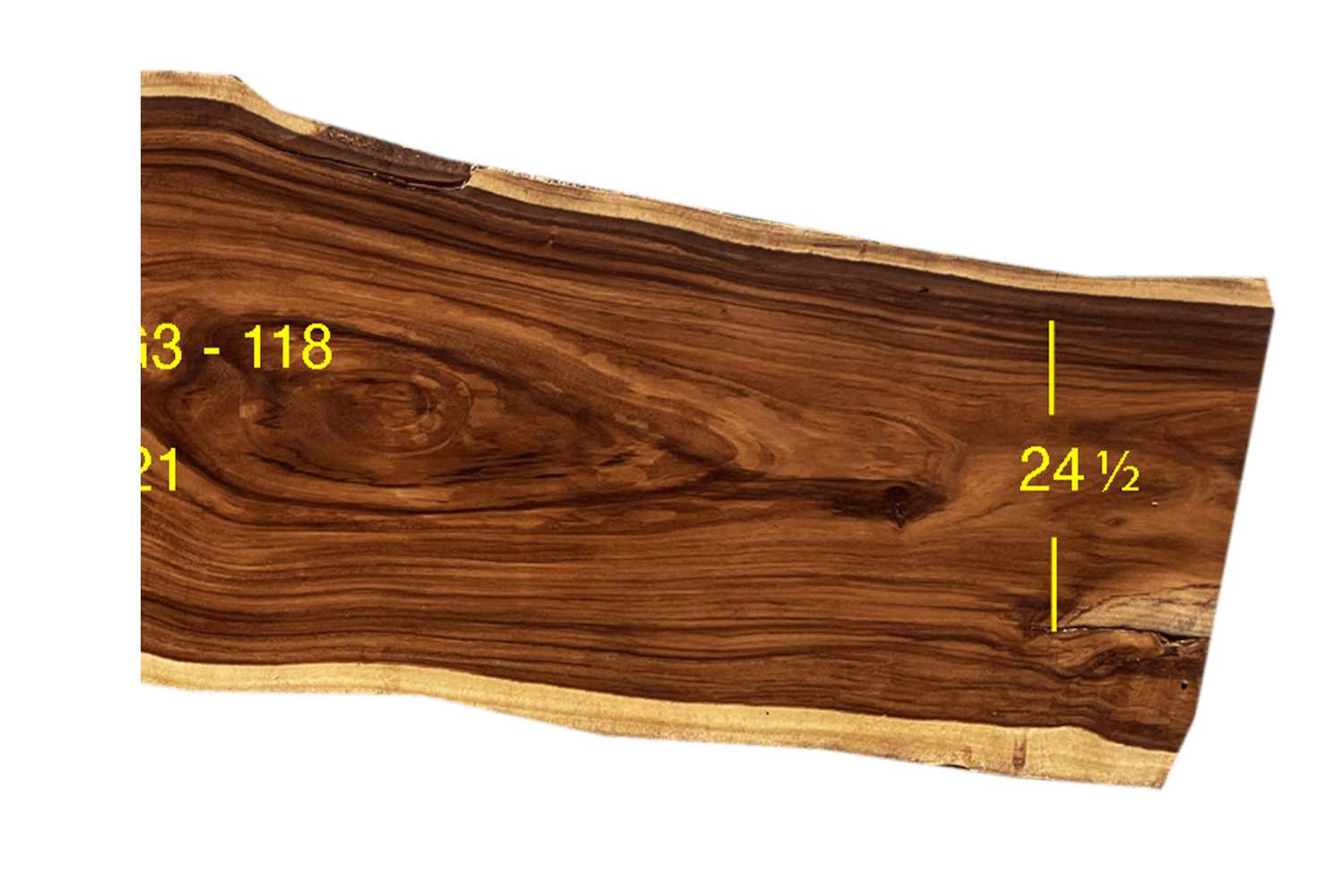

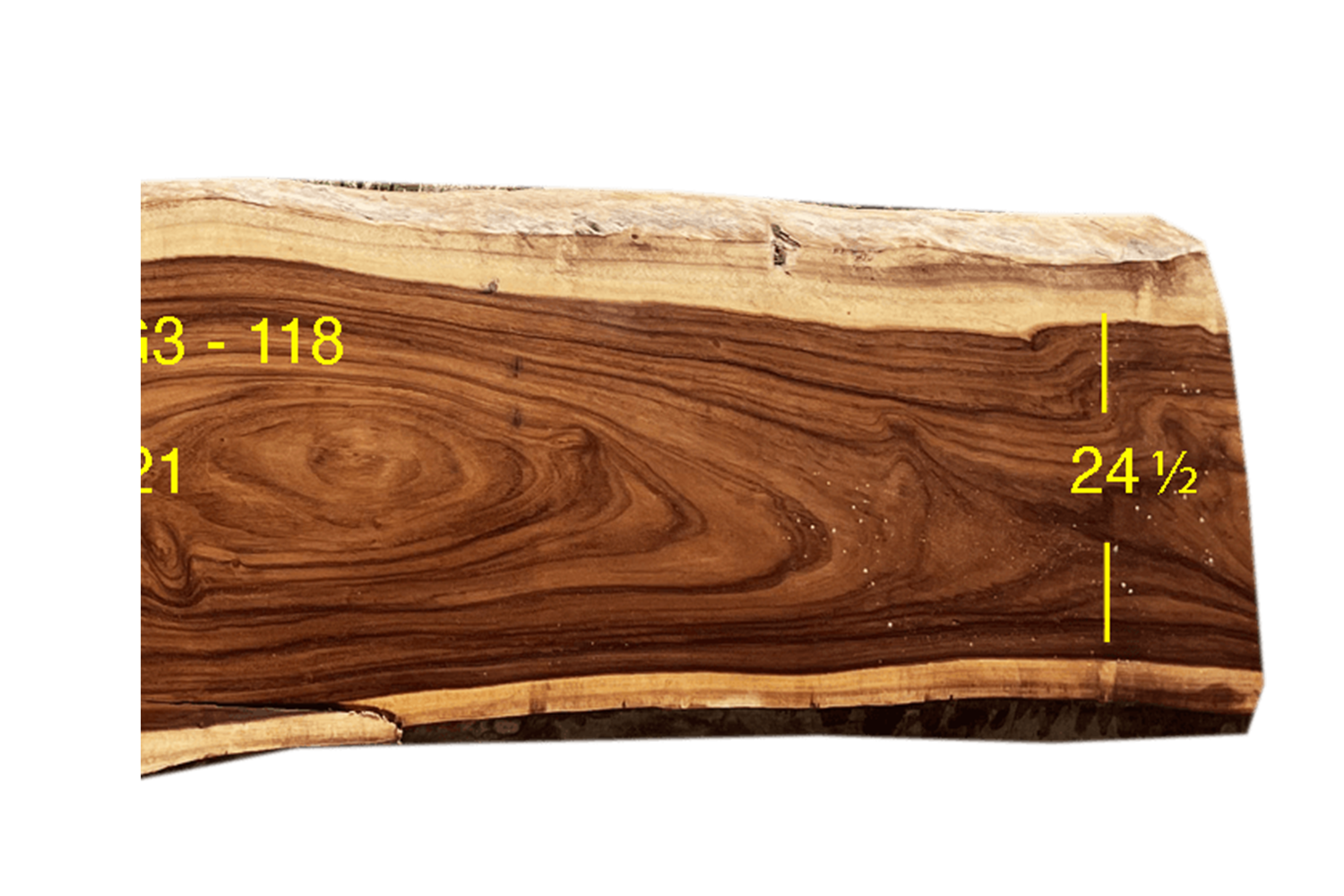

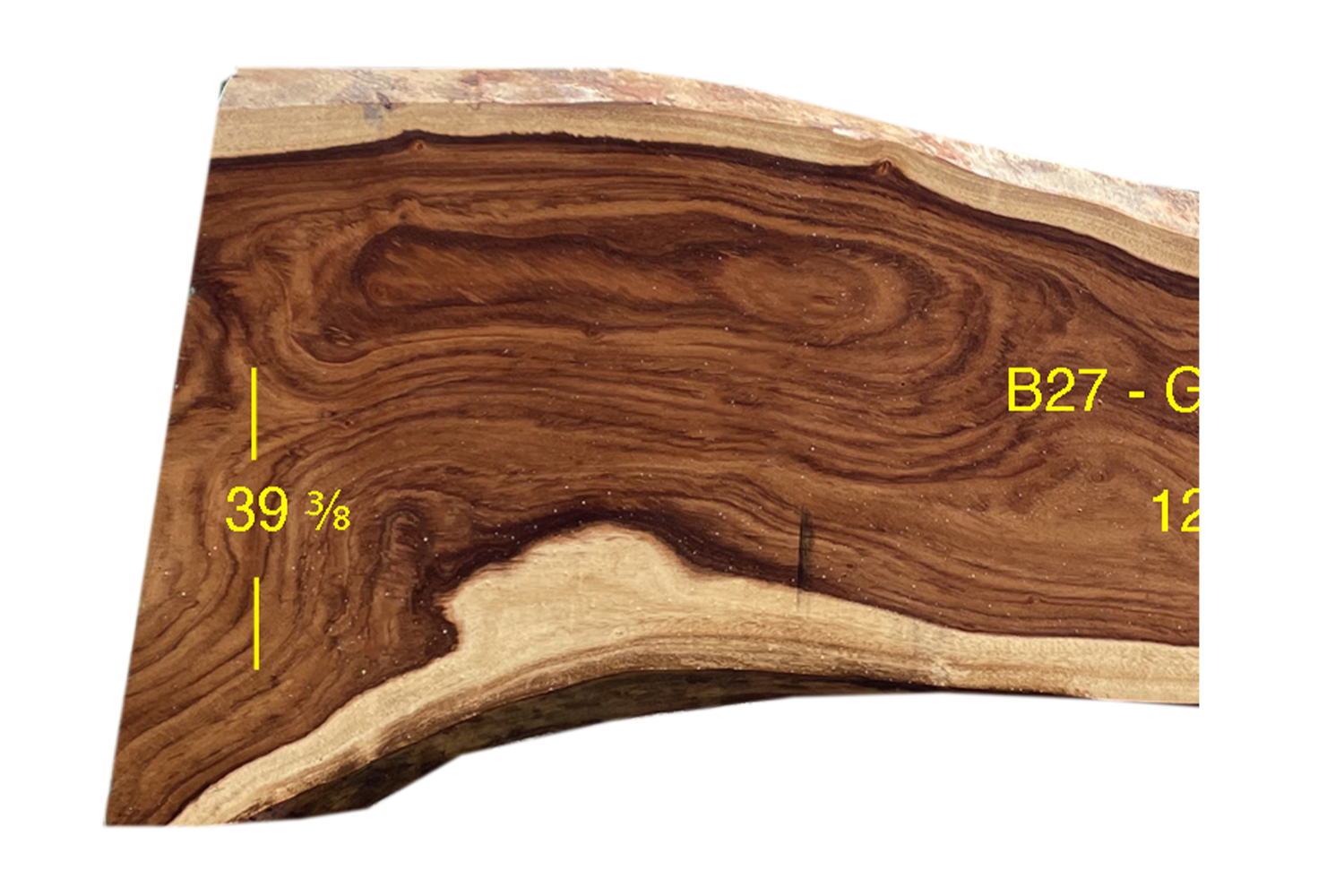

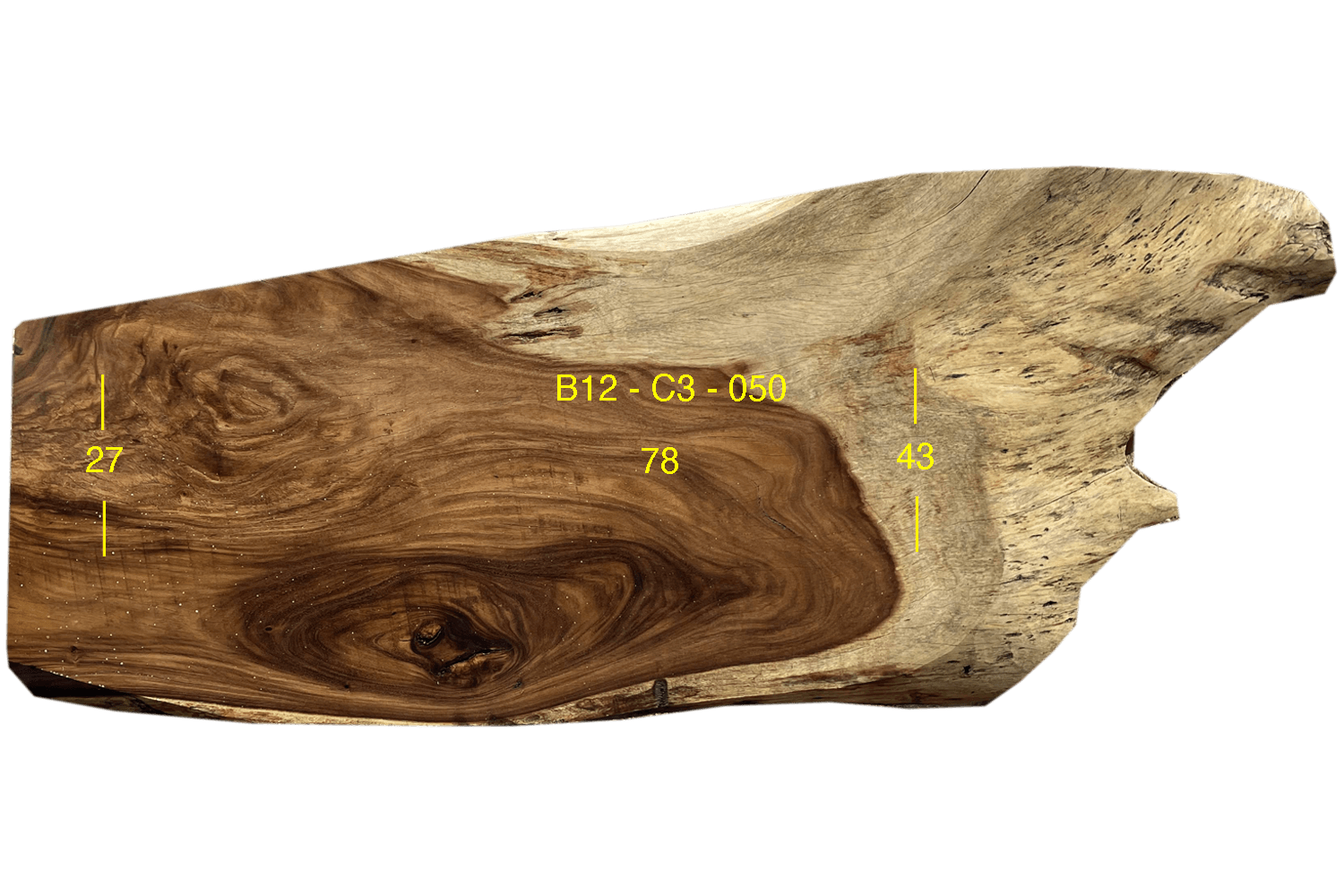

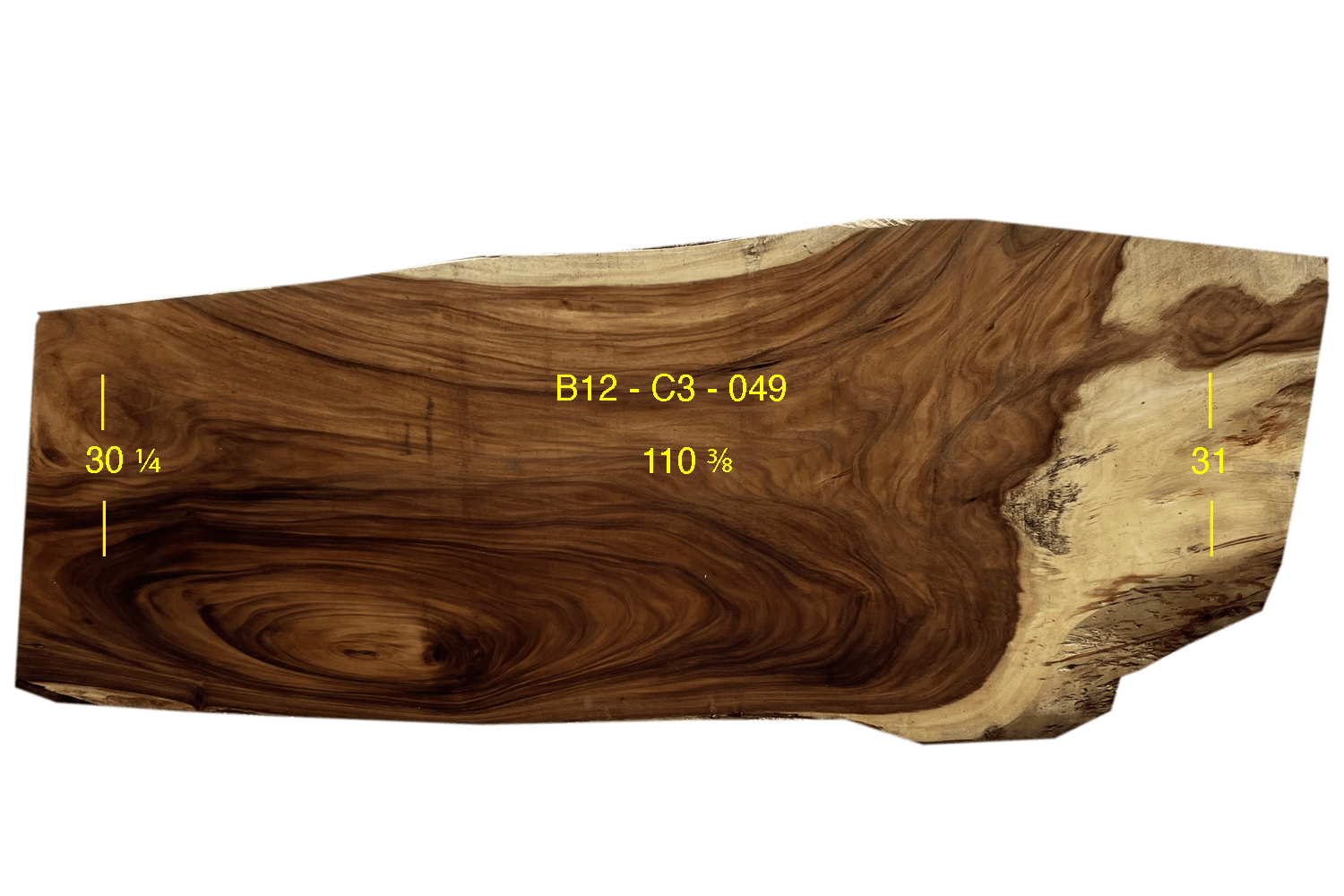

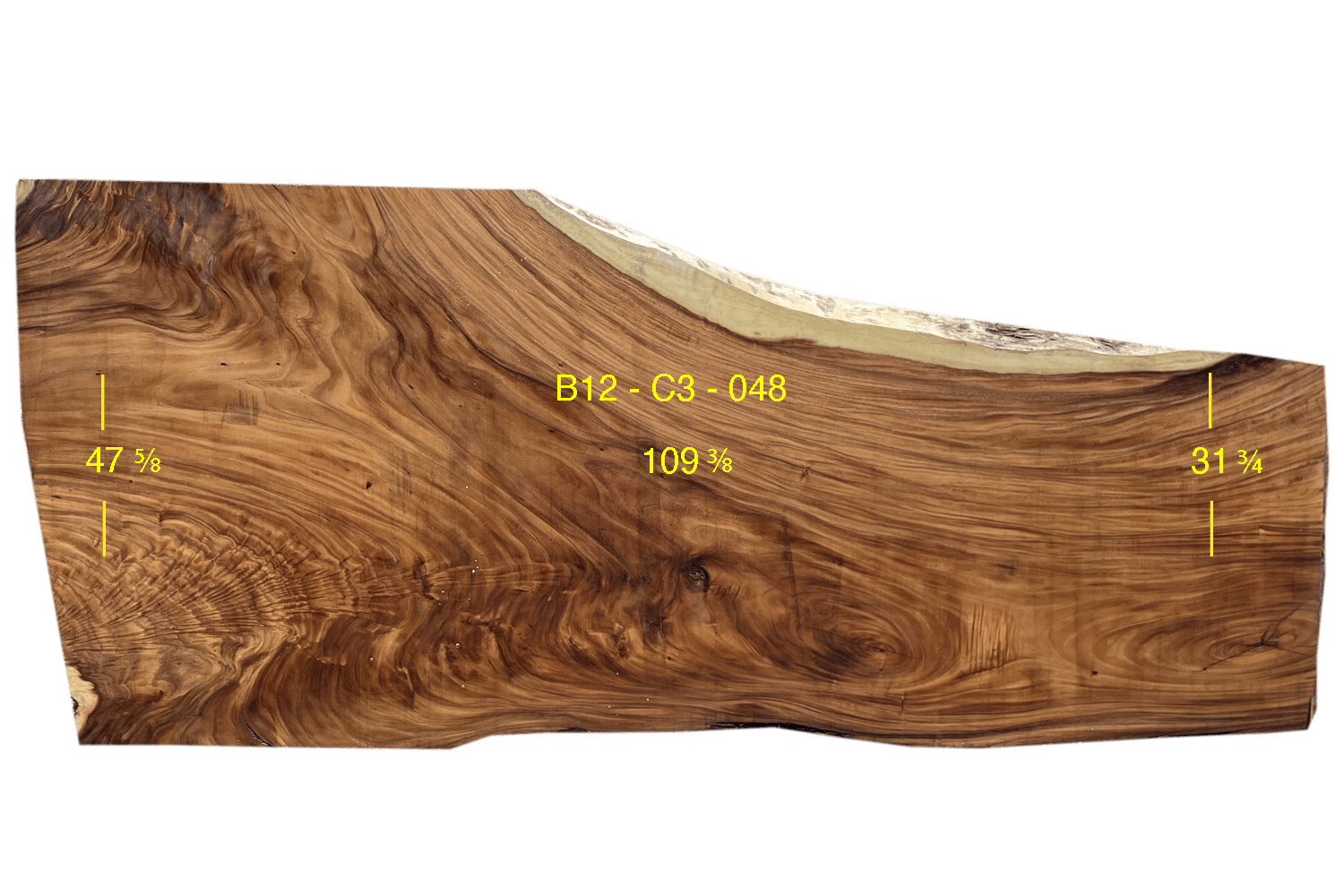

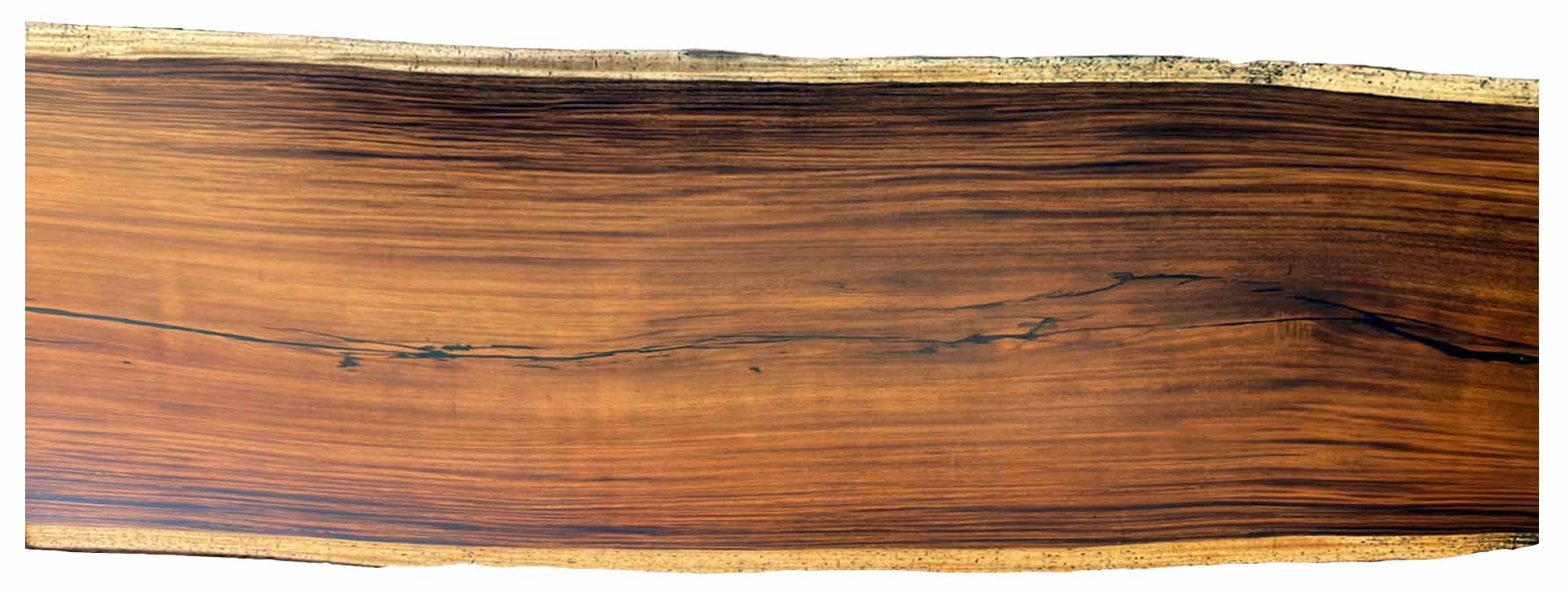

Upon completion of the drying process for Monkey pod and Parota slabs, we meticulously sand them down to a 120-grit finish.

This crucial step reveals the distinctive and aesthetically pleasing grain patterns that were previously concealed.

The application of a small amount of water enhances the visual appeal, providing ample time to capture the authentic appearance of the slab before the final finishing.

Simultaneously, each slab undergoes comprehensive documentation, resulting in the creation of a unique code. This coding system ensures a traceable record, enabling us to correlate each slab with the corresponding image captured during documentation.

The local Ministry of Environment conducts an examination of the designated area, and based on the outcomes, they may either grant or deny approval for tree harvesting.

Our founder, Bernardo Urbina, personally engages in the selection and approval process for Monkey pod and Parota logs, which he procures from local farmers situated in the rural regions of Costa Rica.

Then, with the completion of all the paperwork, the acquisition of a "yellow tag" permit is secured to facilitate the transportation of the logs to the mill.

Upon arrival at the Mill, we undertake the unloading of the logs, conduct a meticulous inventory check, and assign a distinct number to each Monkey pod and Parota log categorizing them based on their size and species.

Bernardo Urbina, along with his team, deliberates on the optimal approach for milling each log, ensuring the production of unique slabs.

Subsequently, as the slabs are processed, they undergo stickering in preparation for their transfer to the warehouse, where the kiln is located.

Each slab is methodically stickered, maintaining a spacing of 12-16 inches, and undergoes a pre-drying phase lasting 1.5 months before progressing to the kiln.

Our kiln infrastructure comprises three carts, each with a capacity of 15 tons, facilitating the drying of 30 slabs per cart—amounting to a total of 90 slabs.

The kiln operates using sophisticated Italian software, integrating four strategically positioned sensors on the slabs to monitor their current moisture levels.

Additionally, the system incorporates relative humidity sensors within the kiln, four exhaust flaps, four bidirectional fans, and an extensive 12-meter-long stainless steel heating source. These components collaboratively function, both synergistically and wirelessly, adhering to a meticulously designed computer program.

This program ensures a gradual and efficient drying process, aligning with our predetermined moisture content specifications.

Upon completion of the drying process for Monkey pod and Parota slabs, we meticulously sand them down to a 120-grit finish.

This crucial step reveals the distinctive and aesthetically pleasing grain patterns that were previously concealed.

The application of a small amount of water enhances the visual appeal, providing ample time to capture the authentic appearance of the slab before the final finishing.

Simultaneously, each slab undergoes comprehensive documentation, resulting in the creation of a unique code. This coding system ensures a traceable record, enabling us to correlate each slab with the corresponding image captured during documentation.

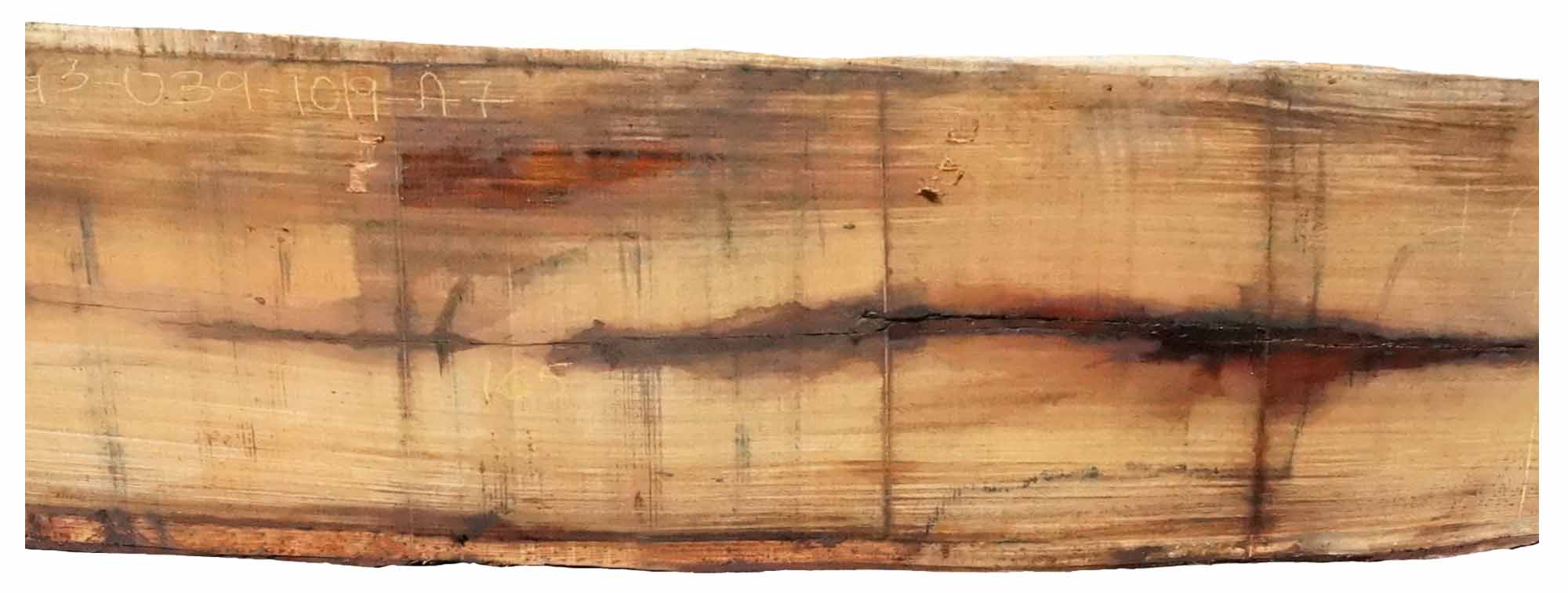

Before/after

Our skilled artisans then transform each piece with expert milling, precise kiln drying, and sanding to a luxurious 120-grit finish.

Before

After

100%

sustainably-harvested slabs

Check Our Inventory

FAQ

Do you ship your products?

Yes we ship our product anywhere in the USA. We offer shipping up to terminal.

What is your normal shipping lead time?

We typically ship our products within 3-7 business days, larger orders may require additional time.

What do I pay for shipping?

Shipping is calculated in real time once you add any product to the cart and then put your address at the checkout page.

Where do you get your wood from?

We are dedicated source for Parota and Monkey pod slabs imported directly from Costa Rica

Is your lumber/slabs kiln dried?

Yes, all of our lumber and slabs are kiln dried.

Do you accept credit cards?

Yes, our website accepts payments from all major credit cards.

Where are you located?

Our inventory is strategically housed in a dedicated facility in South Carolina, ensuring swift shipping for your orders.

Do you offer wholesale price?

Discover the benefits of wholesale pricing for bulk orders and gain access to our competitive rates at just $6.50, FOB. Whether you're a retailer or a business seeking to replenish your stock with top-quality, kiln-dried, and sanded products, we've got your needs covered with budget-friendly solutions.