What is Kiln-Drying and How Does it Affect the Wood?

The main purpose of kiln-drying is to remove excess moisture from the wood, which helps prevent warping, splitting, and cracking. When trees are cut down, they contain a significant amount of water – up to 50% of their total weight. This moisture needs to be removed before the wood can be used for construction or furniture making as it can lead to structural issues and affect the overall quality of the finished product.

The kiln-drying process starts by stacking freshly cut timber into chambers or ovens where heat and dehumidified air are circulated. The temperature inside these chambers can range from 100-140°F (38-60°C), while humidity levels are kept around 25%. The combination of heat and dry air causes the water molecules in the wood to evaporate, thus reducing the moisture content.

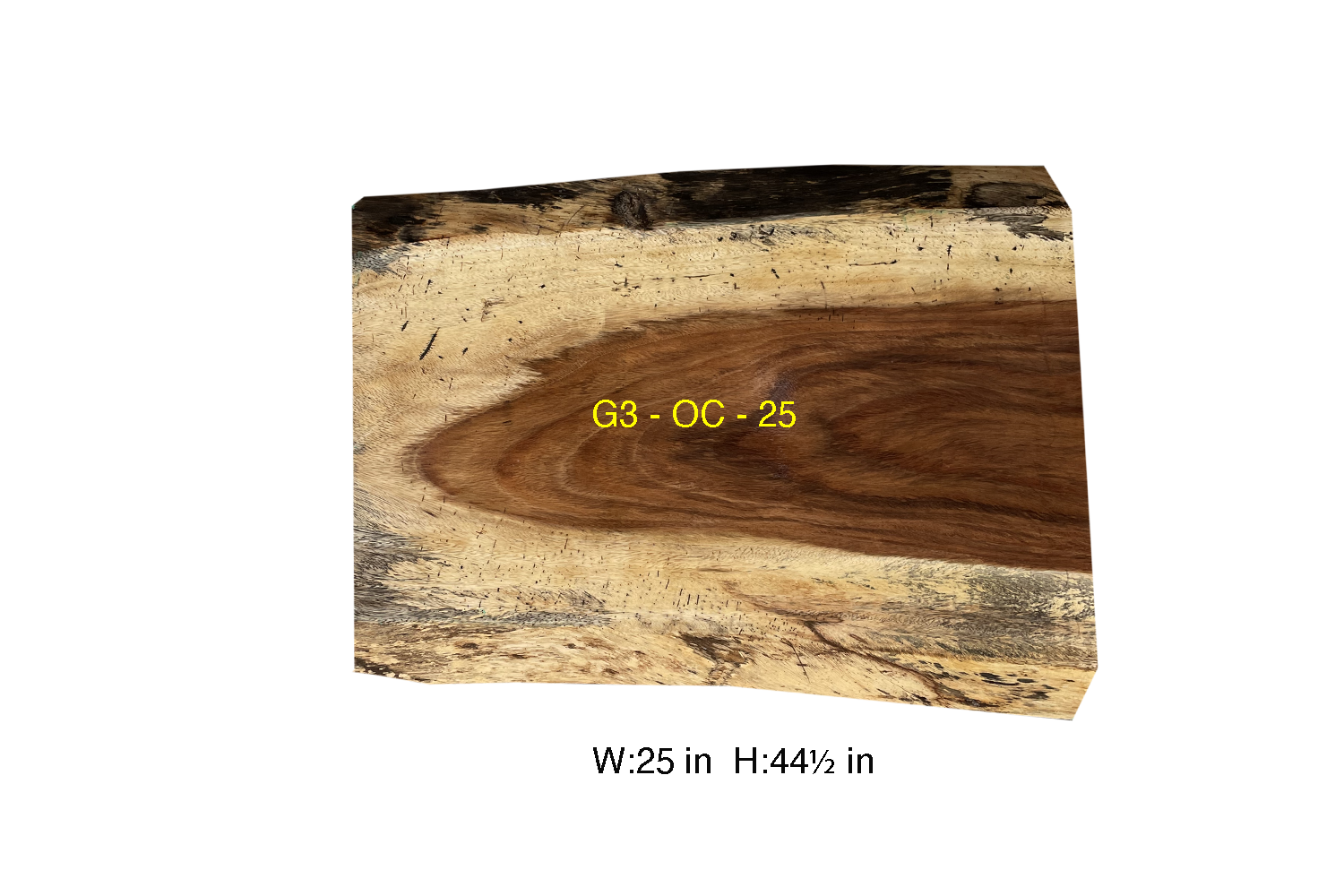

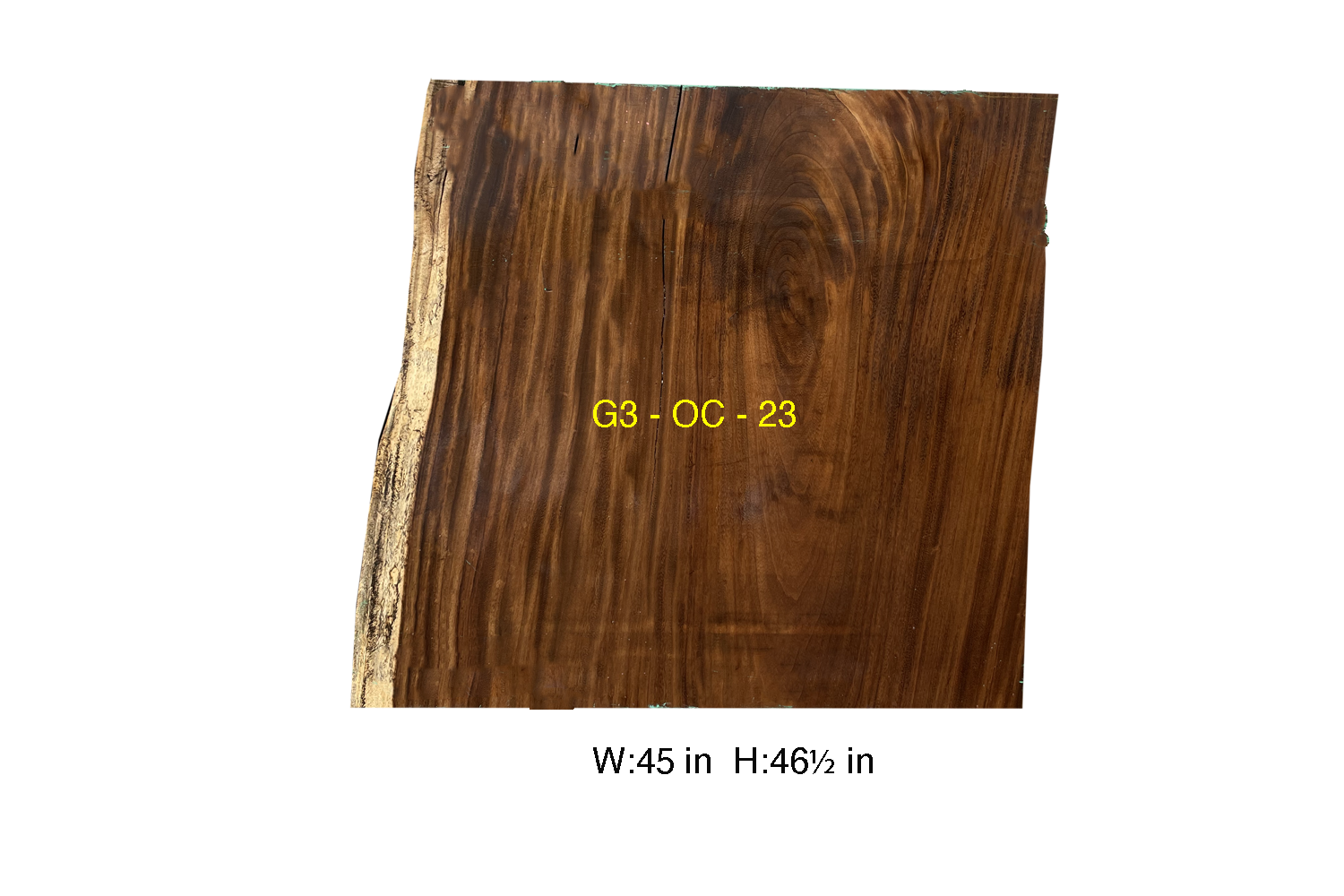

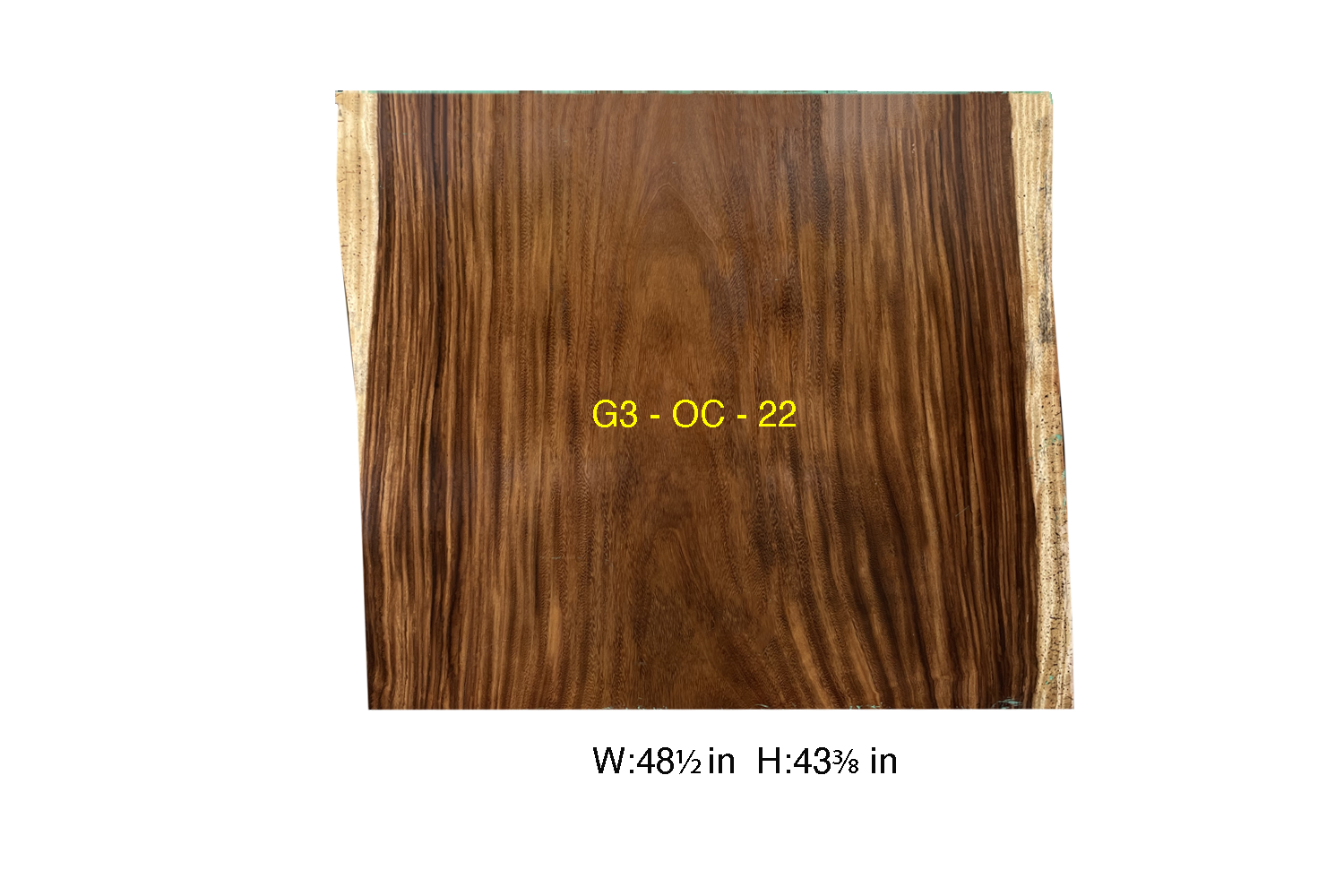

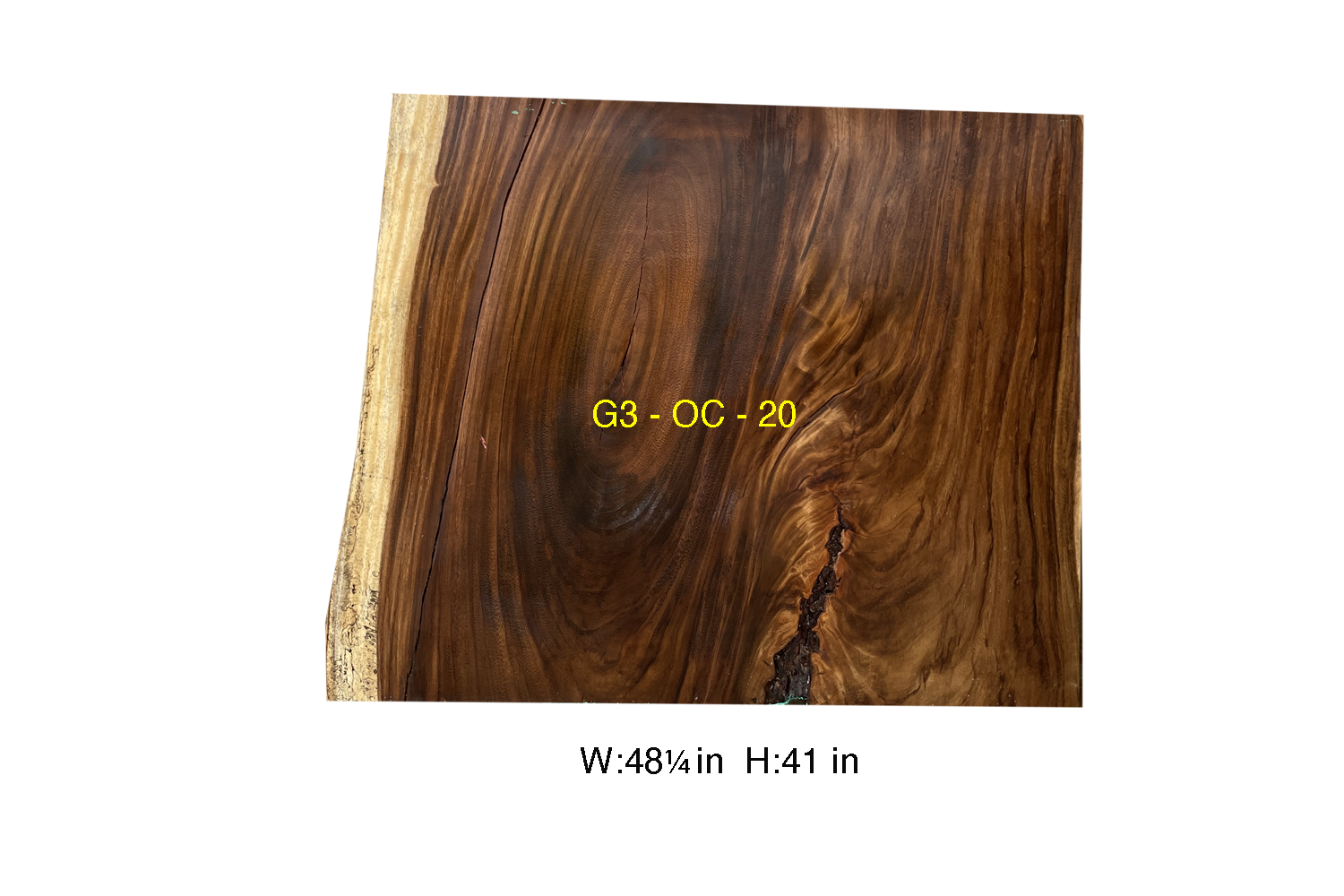

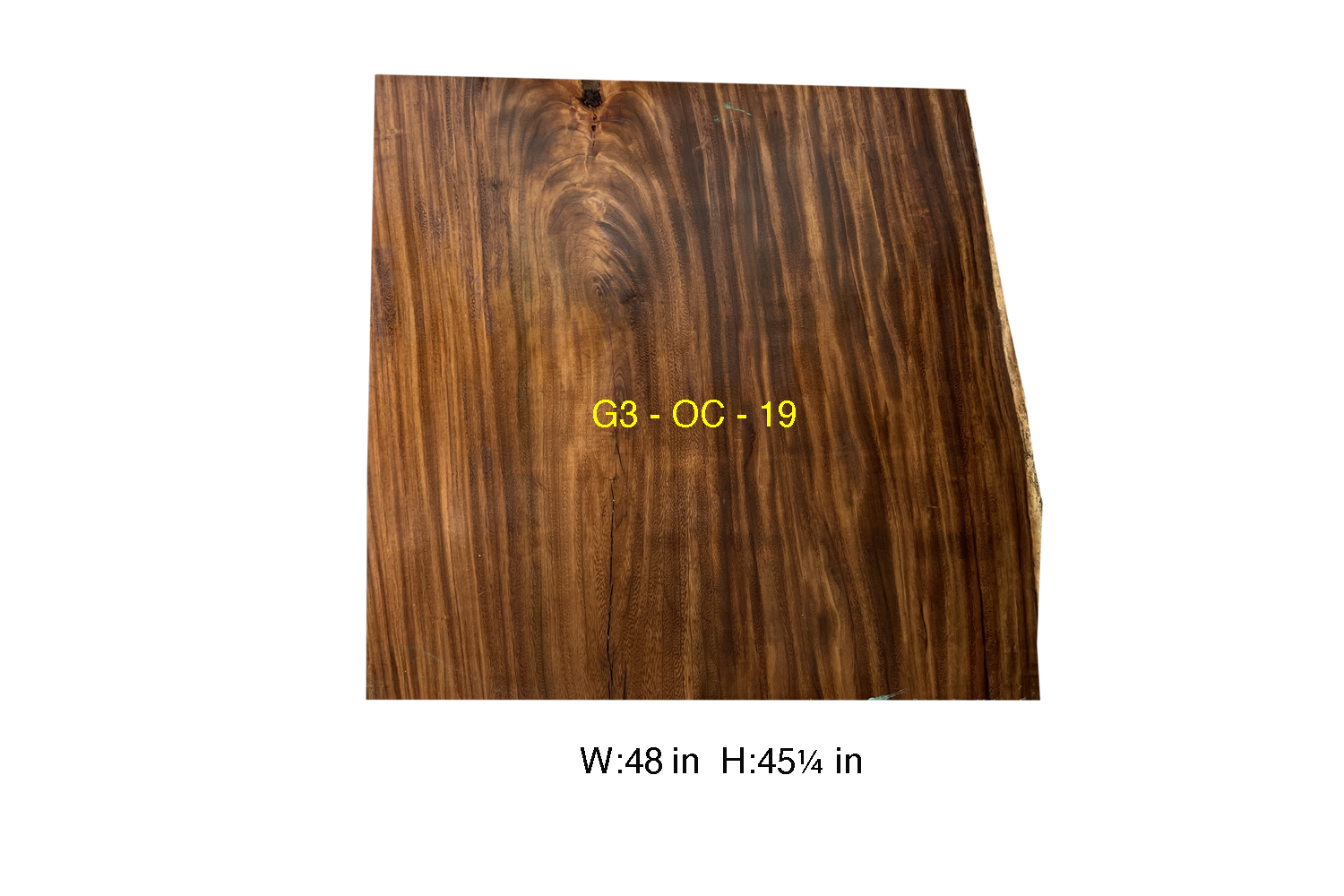

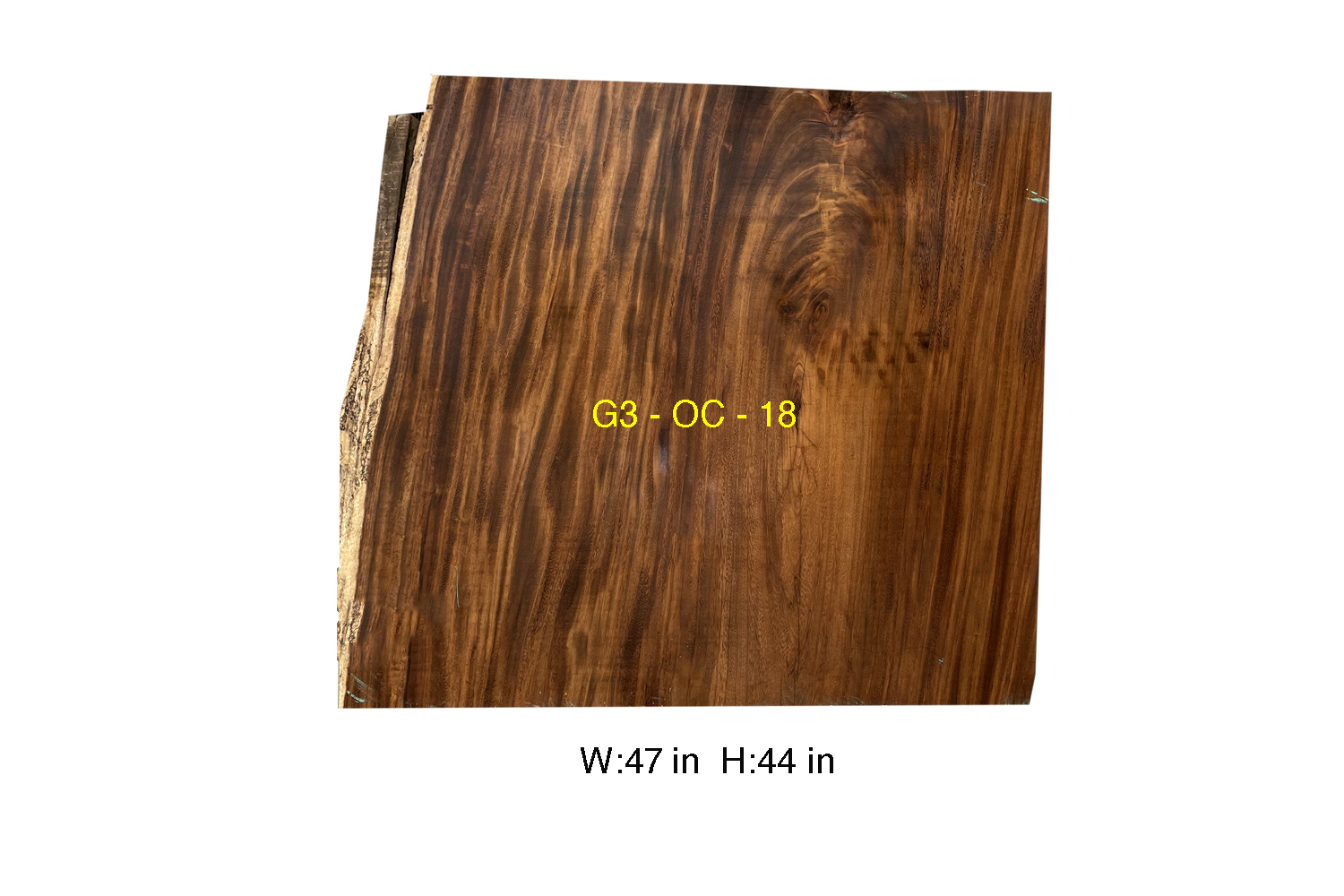

Looking for material for your creative projects? We offer you a diverse selection of Parota and Monkey pod slabs, carefully chosen and prepared, take a look at our website!

5 Reasons Why You Should Use Kiln-Dried Wood Slabs in Your Woodworking Projects

There are several reasons why kiln-dried wood slabs should be a staple in every woodworking enthusiast's workshop. Not only do they offer superior quality and durability, but they also provide a wide range of benefits that make them the perfect choice for any woodworking project.Reason 1: Improved Stability and Reduced Warping

Wood is a natural material that is constantly changing, even after it has been cut and processed into lumber. This change is primarily caused by moisture, as wood absorbs and releases moisture depending on the surrounding environment. When working with wet or green wood, it can be prone to warping, twisting, and cracking as it dries out.

However, kiln-dried wood slabs undergo a specific drying process that greatly reduces the risk of these issues. In this process, the wood is placed in a large oven-like structure called a kiln where it is exposed to controlled heat and humidity levels. This helps to remove excess moisture from the wood in a controlled manner, resulting in a more stable and consistent product.

The reduced moisture content also means that kiln-dried wood slabs are less likely to shrink or expand with changes in temperature and humidity. This makes them an ideal choice for projects that require precision and accuracy, such as furniture making or cabinetry.

Are you a wood enthusiast? At Costa Rica Mill we offer you unique and high quality slabs, contact us here and get them now!

Reason 2: Enhanced Durability and Resistance to Pests

The kiln-drying process involves subjecting the wood to high temperatures in a controlled environment, which removes excess moisture from the wood. This results in a more stable and sturdy material that is less susceptible to damage from environmental factors such as humidity and temperature changes.One of the main benefits of kiln-dried wood slabs is their increased resistance to pests. Insects like termites, beetles, and carpenter ants can cause serious damage to untreated or improperly dried wood. These pests thrive on moisture-rich environments, making kiln-dried wood an unappealing target for them.

Moreover, kiln-drying also kills any existing insects or eggs present in the wood, eliminating the risk of future infestation. This not only protects your projects but also prevents potential harm to other pieces of furniture or structures made with untreated wood.

Reason 3: Better Workability and Finishing Results

One of the main benefits of using kiln-dried wood slabs is the improved workability they provide. As moisture is removed from the wood, it becomes less prone to warping, shrinking, or cracking. This means that it is easier to cut, shape, and manipulate without worrying about unexpected changes in size or shape during the woodworking process.

Moreover, kiln-dried wood slabs have an increased strength-to-weight ratio compared to air-dried or greenwood. This means that they can withstand heavy loads and stresses without breaking or bending easily. As a result, wooden furniture made from kiln-dried slabs is more durable and long-lasting.

Another significant advantage of using kiln-dried wood is the superior finishing results it produces. With minimal moisture content in the wood, there is less risk of paint or varnish not adhering properly or bubbling up due to trapped moisture under the surface. The end result is a professional-looking finish that showcases the natural beauty of the wood grain without any imperfections caused by excessive moisture.

Want to learn more about our products? Explore our extensive inventory of slabs, each of which tells a unique story!

Reason 4: Reduced Risk of Mold or Mildew Growth

Kiln-drying is a process in which the moisture content of the wood is significantly reduced through exposure to controlled heat and humidity. The result is a piece of wood that has a moisture content between 6-8%, making it less susceptible to mold or mildew growth compared to air-dried or green wood.Mold and mildew thrive in moist environments, making kiln-dried wood slabs an ideal choice for woodworking projects. The controlled drying process ensures that the excess moisture in the wood is eliminated, leaving behind a more stable and durable piece of wood. As a result, this reduces the chances of mold or mildew forming on your finished project.

Furthermore, kiln-drying also kills any existing fungi spores that may be present in the wood, ensuring that your project remains free from these harmful microorganisms. This means you can work with peace of mind knowing that your final product will not be affected by mold or mildew over time.

Reason 5: Preserves Natural Color and Beauty of the wood

When wood is harvested, it contains a high level of moisture which can cause warping, cracking, and splitting over time. Traditional air-drying methods can take months or even years to reduce the moisture content to an acceptable level. However, with kiln-drying, this process can be completed in a matter of weeks.

During the kiln-drying process, the temperature and humidity levels are closely monitored and adjusted to ensure that the wood dries evenly without any damage. This controlled environment also prevents fungi and bacteria from growing on the wood, eliminating any risk of rotting or discoloration.

As a result, kiln-dried wood slabs retain their natural color and beauty as opposed to traditional air-dried pieces that may have uneven coloring or visible signs of decay. The end product is a stunning piece of wood with rich tones and smooth textures that are perfect for any woodworking project.

We are a dedicated source for Parota and Monkey pod slabs. Connecting passionate woodworkers with exquisite and carefully selected materials. For more tips and information, follow us on Facebook and Instagram. Discover all our products at CostaRicaMill.com